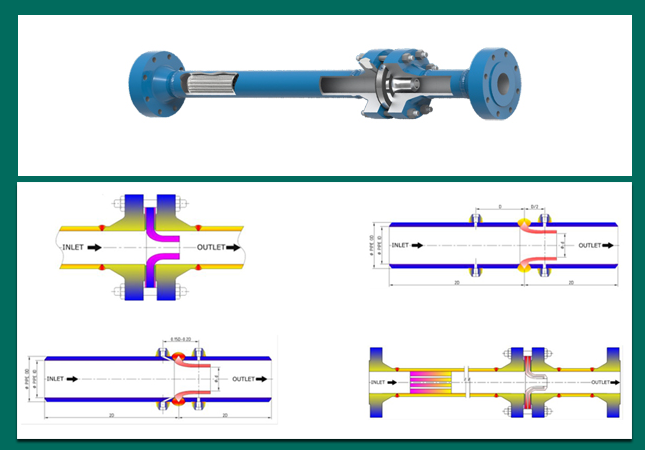

Flow Elements - Flow Nozzles Assemblies

Description :

FEPL's flow nozzle is a flow measurement device which used for measurement of high velocity flow, such as high pressure steam. It can also be used with other fluids such as water, air or other gases. The typical profile of this device offers a smooth passage to the fluid which leads to the lesser pressure drop and thus more efficiency. The rounded profile is particularly useful when the steam contains particles which damage the edges of the flow element which doesn't happen due to the smooth profile. Thus the product life is increased.

Salient Features :

• Best suitable for measurement of high pressure high temperature high velocity steam measurement.

• Smooth profile and rigid structure makes the assembly extremely stable

• Free from leakage (when provided in weldin type assembly).

• Zero maintenance since no moving parts.

• Repeatability: 0.3%

• Less straight lengths requirement.

Design & Manufacturing Standard :

• ISO-5167 part III

• ASME PTC-19.5

• ASME PTC-6

Materials :

Selection based on temperature and process conditions.

Typically used materials are :

Typically used materials are :

• Element : SA.182 F316

• Pipe: SA.106Gr. B / SA335 P11 / SA335 P22 / SA.335P91

• Flange material : SA105 / SA182F11 / SA182F22 / SA182 F91

Classifacation :

The flow nozzle can be classified as follows

BASED ON ELEMENT

• Long Radius High Beta

• Long Radius Low beta

• ISA 19 32

BASED ON MOUNTING

• Weldin type

• Flanged type

• Holding ring type

BASED IN APPLICATIONS

Used in high accuracy area of turbine steam flow measurement Flanged type with

throat tap nozzle (as per PTC-6 standard) with accuracy in a tune of 0.25%.

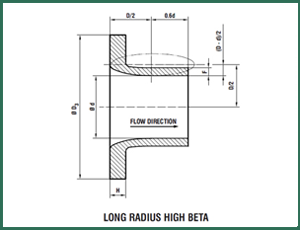

Long Radius High Beta Type Nozzle :

Long Radius High Beta Type Nozzle :

This type of nozzle uses an elliptical profile. The quarter portion of the ellipse is used to form the nozzle profile. This is a commonly used nozzle type with an uncertainty of 2% irrespective of beta ratio. This can be offered in all the 03 mounting classifications.

• Size limits : 50 mm to 630 mm

• Beta Ratio : 0.2 to 0.8

• Reynold's Number : 10^4 to 10^7

• Pressure tapping : D – D/2

A Weldin type assembly typically with a pipe length 750 mm on upstream side and 250 mm on downstream side. Flanged type assembly can be supplied with or without spool piece as per requirement.

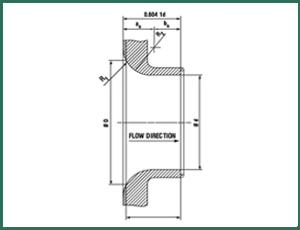

ISA 1932 TYPE NOZZLE :

The profile of this type of nozzle is formed with the intersection of 2 circles. This gives an estimated uncertainty of 0.8% to 1.2%, depending on the beta ratio. This can be offered in all the 03 mounting classifications. But this has certain manufacturing limitations to use with weldin type, when the line size is small. Size limits: 50 mm to 500 mm Beta Ratio: 0.3 to 0.8

Reynold's Number :

For beta 0.3 to 0.44 à 7 x 10^4 to 10^7

For beta 0.44 to 0.8 à 2 x 10^4 to 10^7

Pressure tapping :

Pressure tapping :

Upstream tap Corner tap

Downstream tap » @ 0.15D for beta < 0.67

» @ 0.2D for beta > 0.67

Downstream tap > corner tap

A Weldin type assembly typically with a pipe length 750 mm on upstream side and 250 mm on downstream side.

Flanged type assembly can be supplied with or without spool piece as per requirement.

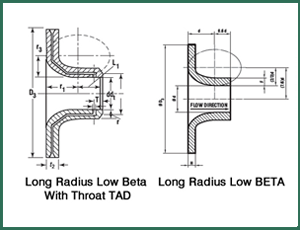

Long Radius Low Beta Type Nozzle :

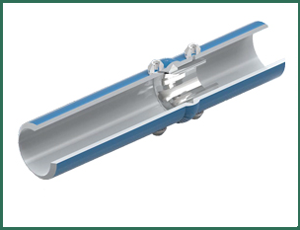

This type of nozzle also uses a quarter elliptical profiles.This type of nozzle is used for performance testing of turbines, as per PTC standard. When supplied with the typical assembly as per PTC-6, uncertainty is 0.25%.

Long Radius Low Beta Type Nozzle :

This type of nozzle also uses a quarter elliptical profiles.This type of nozzle is used for performance testing of turbines, as per PTC standard. When supplied with the typical assembly as per PTC-6, uncertainty is 0.25%.

• Size limits : 50 mm to 630 mm

• Beta Ratio: 0.2 to 0.5

• Reynold's Number : 104 to 107

• Pressure tapping

• Upstream tap @ D

• Downstream tap Throat tap (through element)